AQUA-TOR 420 aeration system

The AQUA TOR aeration systems based on the AR-420 T(N) toroidal aerators with an elastic perforated membrane are designed for aeration of the sludge mixture (wastewater with active sludge).

The toroidal aerators with rubber perforated membrane are available in two models – AR-420T and AR-420N. Both models have the same operating principle, but differ only in the attachment to the aeration module.

Basic design of AR-420N (a) and AR-420T (b) aerators

1 – perforated elastic membrane; 2.1 and 2.2 – aerator housing; 3 – splitter; 4.1, 4.2 – rubber bushing; 5 – uPVC/PE air distribution pipe (module) Ø90 / 110 mm; 6 – PE air distribution pipe (module) Ø 110 mm; 7 - bracket; 8 - pin; 9 - cog wedges.

The perforated elastic membranes are structurally unified for both models and, based on the operating conditions, can be made of different materials:

Variants of elastic perforated membranes for AR-420 T(N) aerators:

- EPDM (ethylene-propylene rubber) - for operation in municipal and industrial wastewater;

- An EPDM membrane covered with PTFE layer (polytetrafluoroethylene) – for operation in chemically aggressive wastewater;

- silicone – for operation in high-temperature aggressive industrial wastewater;

- polyurethane – for operation in wastewater with a specific composition.

The delivery package of the AQUA-TOR aeration system includes:

- AR-420 T(N) aerators;

- aeration module attachment system;

- downcomers and manifolds;

- the manifold and aeration module supports.

The configuration of the aeration system is developed subject to the geometry of the aeration tanks and the need for air to oxidize the contaminants and mix the sludge.

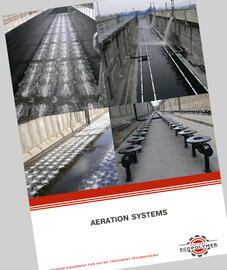

Variant of AQUA-TOR aeration system configuration

1 – downcomer; 2 – manifold; 3 – aeration module; 4 – aeration module attachment system; 5 – manifold fitting system; 6 – AR-420 T(N) aerator complete with the module attachment system.

| Parameter name | Unit of measurement | Value |

|---|---|---|

| Outer diameter | mm | 420 |

| Inner diameter | mm | 170 |

| Aerated surface area | m2 | 0,115 |

| Oxygen transfer efficiency | %/m | 6,6÷9,3 |

| Hydraulic resistance | m H2O | 0,15÷0,4 |

Aerator capacity: - Minimum - Optimum - Maximum | m3/h | 5 10÷15 18÷20 |

| Air bubble size | mm | 1÷2 |

- more intensive mixing of active sludge, as well as mixing of active sludge with wastewater is due to the "airlift" effect, which prevents the formation of stagnant zones and sedimentation of sludge at the bottom of the aeration tank;

- the flow of the sludge mixture through the central hole reduces the flare coalescence of air bubbles, and ensures increase in the mass transfer coefficient.

Scheme of the sludge mixture movement when using the toroidal (left) and disk (right) aerator

It has been experimentally proven that the toroidal design ensures increase in the mass transfer coefficient by 15-20% compared to disk aerators.